Supporting the emergency effort against COVID-19

At the height of the global pandemic, a number of UK manufacturers worked with the government to produce life -saving equipment in a short space of time and within tight production restrictions.

PSM were such an amazing company at helping my team at Dyson create many components for our ventilator. I really thank them for all of their help during our adventure. I haven’t worked with a better company.

Head of engineering

Engineering capabilities put to the ultimate test

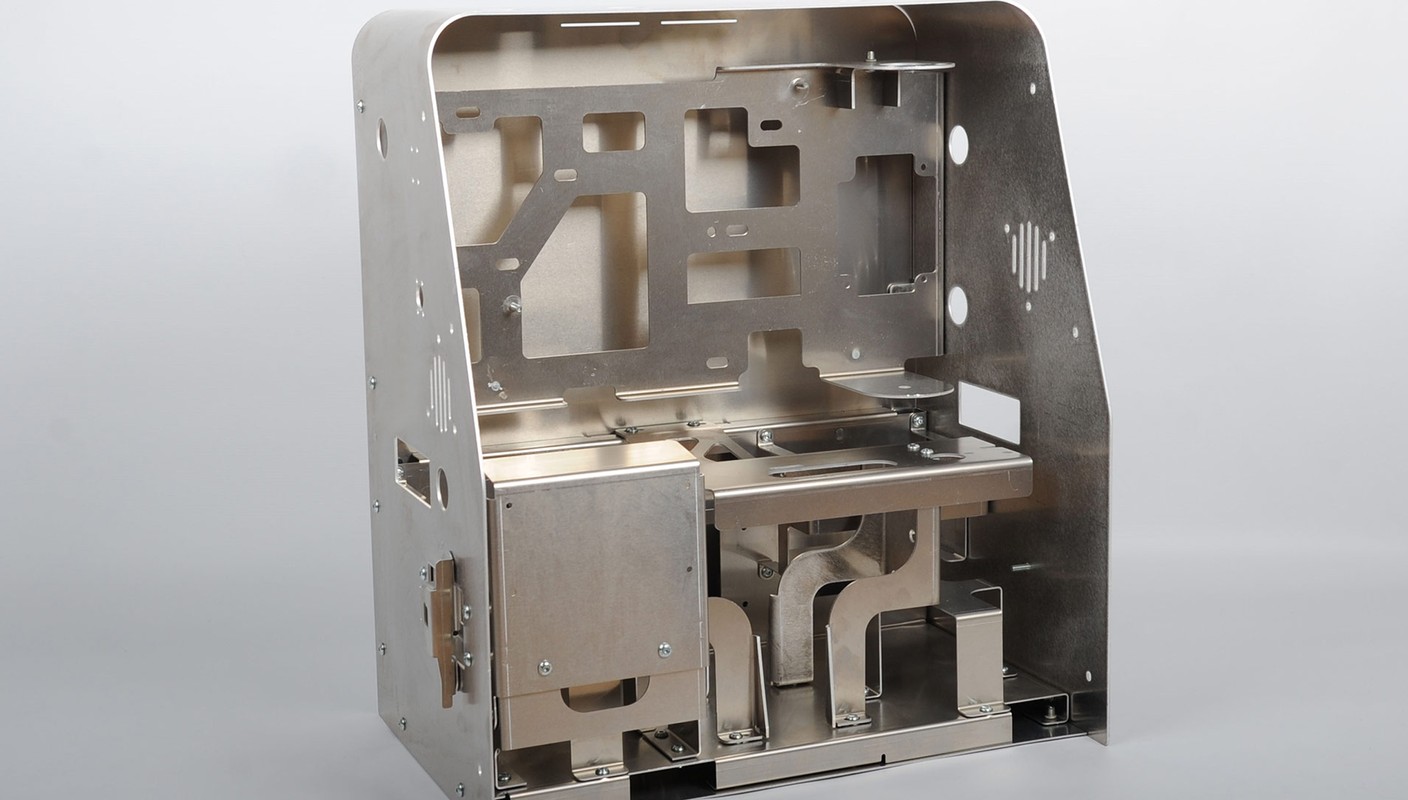

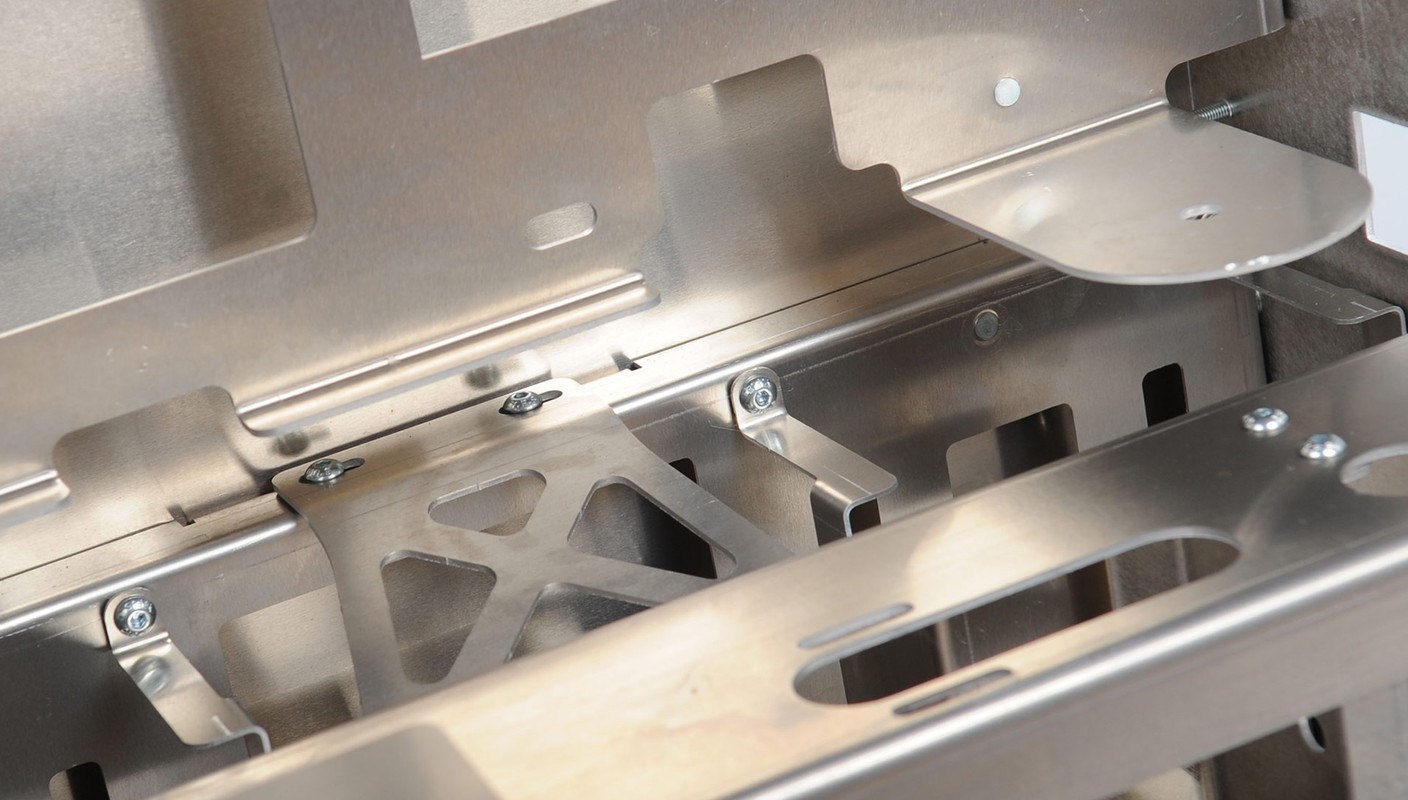

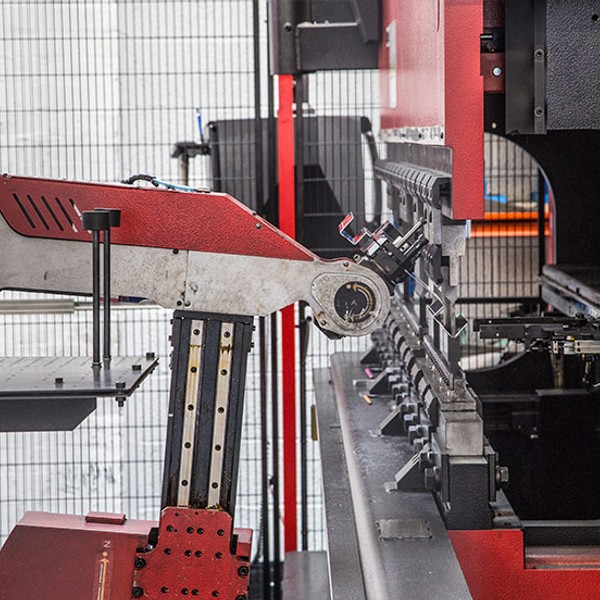

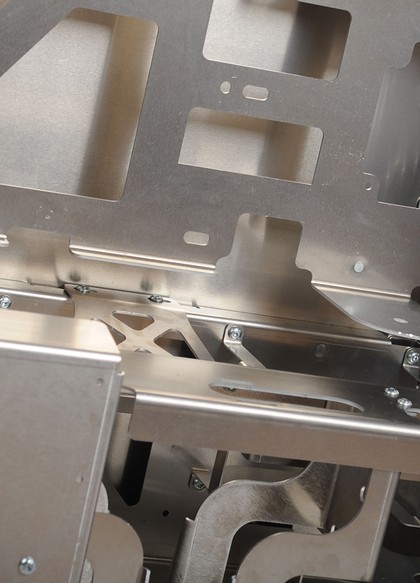

When the Dyson engineering team were set the task of building ventilators at the height of the pandemic, they needed a production partner they could trust to deliver a complex metal assembly to house the ventilator. Having previously worked with PSM on a battery tray for their electric vehicle, Dyson approached us for help. Working literally day and night, our team of engineers sat alongside Dyson’s team to build prototypes that could be immediately scaled up to be produced in the 10,000s.

No project has tested our skills and expertise in such extreme timescales, and we are rightly proud of our contribution. The final assemblies were made from numerous complex aluminium subcomponents that were fixed and welded to form a final case that housed the ventilator. Involving complex geometry, a key challenge was to produce a case that was capable of being built at speed, whilst retaining the precision required for medical equipment.